As humanity’s ambitions to explore and settle beyond Earth continue to grow, new and innovative technologies are emerging to support space exploration and colonization. Among these groundbreaking advancements, space factories and 3D printing in space stand out as game-changers. These technologies not only hold the potential to dramatically reduce costs and improve efficiency in space missions but also enable the creation of self-sustaining human habitats in space. In this article, we will explore how space factories and 3D printing in space are set to revolutionize space exploration, the challenges that come with these technologies, and their potential for the future of humanity in space.

1. Introduction: The Need for Space Factories

Space exploration, especially manned missions to the Moon, Mars, and beyond, is a complex and resource-intensive endeavor. Traditionally, space missions rely heavily on Earth-based manufacturing and supply chains, with materials and equipment being transported to space. However, as missions extend further into the solar system, the costs and challenges associated with transporting everything from Earth become prohibitive.

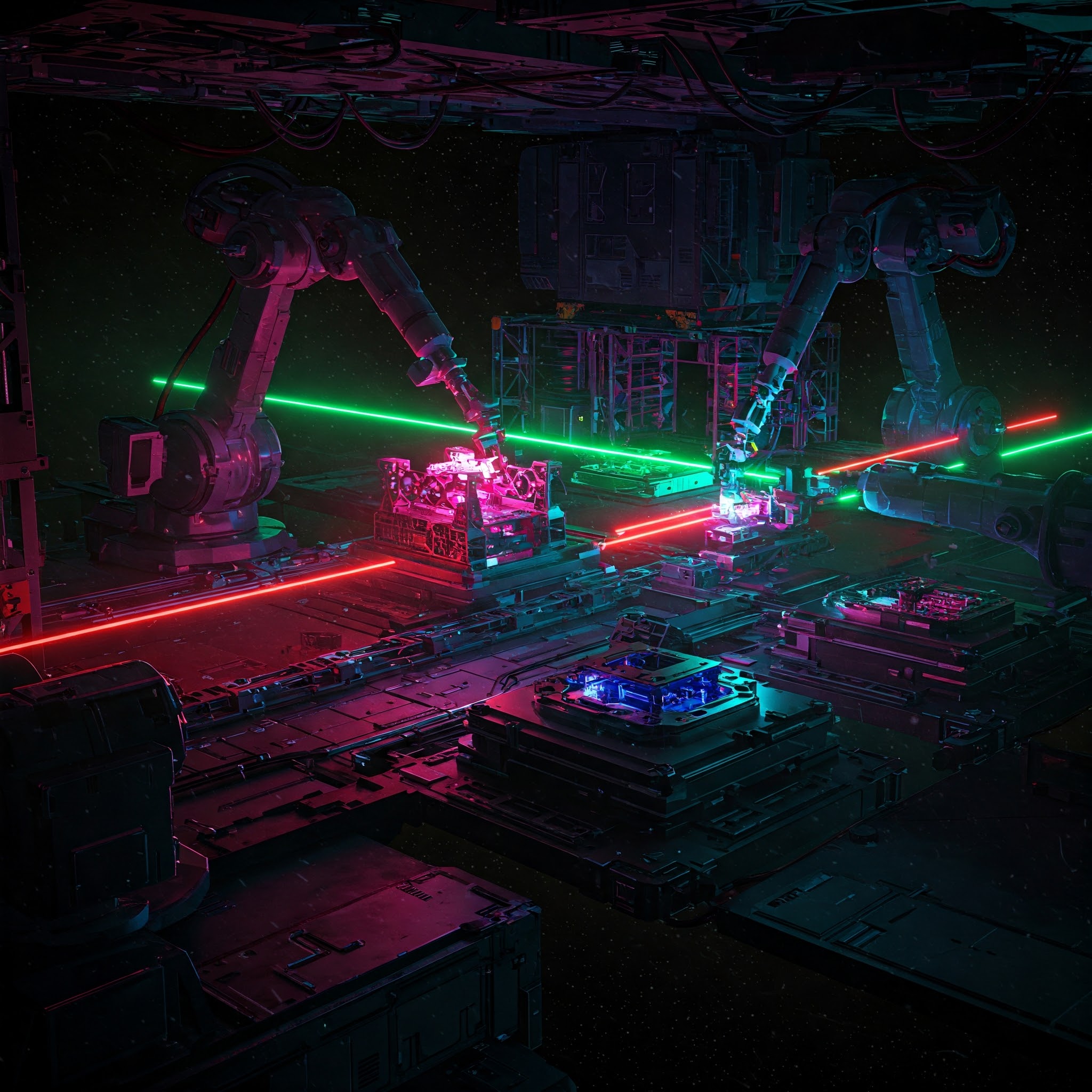

To solve this, the concept of space factories is emerging. These space-based manufacturing facilities would operate in orbit or on celestial bodies like the Moon or Mars, where they would produce materials, products, and even infrastructure using local resources. Space factories would be capable of producing items such as spacecraft components, tools, and potentially even construction materials for space habitats or colonies, all while drastically reducing reliance on Earth-based supply chains.

2. The Role of 3D Printing in Space

A key enabler of space factories is 3D printing, or additive manufacturing, which allows for the creation of objects by layering materials in precise patterns based on digital models. 3D printing has already made significant strides in Earth-based industries, and its application in space holds immense potential.

In space, traditional manufacturing methods such as machining, casting, or welding are often impractical due to the lack of gravity and the challenges posed by extreme temperatures and the vacuum of space. 3D printing, however, can create highly complex structures without the need for molds or special equipment, making it an ideal solution for manufacturing in space.

2.1 How 3D Printing Works in Space

3D printing in space works in much the same way as on Earth but with some additional considerations. Instead of using conventional materials like metals, plastics, or ceramics, the printer uses specialized materials suited for space conditions. These materials may include polymers, metals, or even regolith (the loose, fragmented material found on the Moon or Mars) to create a wide range of objects, from simple tools to more complex components for spacecraft or habitats.

The process involves:

- Designing the Object: Engineers create a digital model of the item to be printed using Computer-Aided Design (CAD) software.

- Material Selection: A 3D printer in space can use a variety of materials, including those that are available on-site (such as lunar or Martian regolith) or transported from Earth.

- Printing the Object: The 3D printer then prints the object by layering the selected material in precise patterns according to the design. The object is built layer by layer, allowing for complex geometries and customization that would be difficult or impossible with traditional manufacturing techniques.

- Post-Processing: After printing, the object may undergo finishing processes like polishing or assembly, depending on the application.

2.2 3D Printing Technologies for Space

Several types of 3D printing technologies are being considered for use in space, each with its unique advantages:

2.2.1 Fused Deposition Modeling (FDM)

FDM is one of the most commonly used 3D printing methods, and it is highly adaptable for use in space. In this method, a material (usually a plastic or polymer) is heated and extruded through a nozzle to build up layers. FDM is particularly suitable for printing parts that are not subjected to extreme stresses and are mostly for prototypes or non-structural components.

2.2.2 Selective Laser Sintering (SLS)

SLS uses a laser to sinter powdered materials (such as metal or plastic) to create a solid structure. This method allows for high precision and is suitable for manufacturing more complex and durable components like tools, parts for spacecraft, or structural elements for habitats.

2.2.3 Direct Energy Deposition (DED)

DED involves using a laser or electron beam to melt material, which is then deposited onto a surface to form the object. This method is especially effective for creating metal components and repairing parts in space, such as spacecraft components that may need to be replaced or repaired during long missions.

2.2.4 Regolith-Based 3D Printing

One of the most promising areas of 3D printing for space exploration is the use of regolith, the soil-like material found on the Moon and Mars. Regolith-based 3D printing would allow space missions to use local resources to create building materials for habitats, landing pads, and other infrastructure. This process not only reduces the need to transport materials from Earth but also supports the vision of sustainable off-world colonies.

3. Applications of Space Factories and 3D Printing in Space

Space factories and 3D printing technologies offer a wide range of applications in space exploration, from manufacturing spacecraft components to building habitats for astronauts. Below are some of the most significant applications:

3.1 Spacecraft and Component Manufacturing

In current space missions, most spacecraft are assembled on Earth and then launched into space. This process is expensive and involves transporting massive amounts of materials. With space factories and 3D printing, components for spacecraft, such as propulsion systems, structural elements, and even electronics, could be manufactured in orbit. This would reduce the need for costly and time-consuming launches from Earth.

3.2 Building Habitats and Infrastructure

For long-term missions, such as establishing a human presence on Mars or the Moon, building self-sustaining habitats is essential. Using 3D printing, astronauts could manufacture their own shelter, life-support systems, and even agricultural tools, all directly on-site. This capability reduces the amount of materials that need to be transported and can support the construction of entire colonies.

3D printing could also be used to create landing pads, roads, and other infrastructure on the Moon and Mars. By utilizing local resources like regolith, space-based manufacturing could become a cornerstone of human colonization beyond Earth.

3.3 Manufacturing Spare Parts and Tools

One of the major challenges of space exploration is the difficulty in obtaining spare parts and tools when something breaks down. With space factories and 3D printing, astronauts can create replacement parts and tools on-demand, ensuring that mission objectives are not delayed due to equipment failure. This also reduces the need for large payloads of spare parts, making missions more cost-effective.

3.4 Medical Applications

3D printing in space could also revolutionize medical care during long-duration space missions. By printing custom medical devices, tools, and even prosthetics, astronauts can ensure that they have the equipment needed to address health issues during their missions. In extreme cases, 3D printing could even enable the production of biological tissues or organs, further extending the potential for human survival in space.

3.5 Astronomical Instruments and Scientific Research

Space factories and 3D printing can be used to create sophisticated instruments for scientific research in space. These instruments can be tailored to the specific needs of a mission, and their construction on-site would make it easier to customize and adapt them as required.

4. Challenges and Limitations of Space Factories and 3D Printing in Space

While the potential of space factories and 3D printing is immense, there are still significant challenges that need to be addressed before these technologies can be fully implemented in space missions.

4.1 Material Constraints

3D printing in space requires materials that are capable of withstanding the harsh conditions of space, including radiation, temperature fluctuations, and the vacuum of space. While metals, polymers, and ceramics are used on Earth, the ability to use these materials effectively in space is still being studied. Furthermore, finding ways to print with local resources like regolith is a complex challenge that requires extensive research and development.

4.2 Energy Requirements

Running a space factory and 3D printers in space requires a significant amount of energy, which could be a limiting factor, especially on missions to distant destinations like Mars. Solar panels or nuclear power systems will be required to provide the necessary energy, and managing this power on a continuous basis will be critical.

4.3 Precision and Reliability

The precision of 3D printing in space must be extremely high, particularly when creating critical components for spacecraft or habitats. Any failure in manufacturing could jeopardize the success of the mission. Ensuring that 3D printers and space factories are reliable in the harsh space environment will be essential for the success of these technologies.

5. The Future of Space Factories and 3D Printing in Space

As space exploration moves toward longer and more complex missions, the role of space factories and 3D printing will continue to grow. Ongoing research and development are likely to solve many of the current challenges, making space manufacturing a viable option for future missions. With advancements in automation, material science, and energy efficiency, space factories may soon become an integral part of human missions to Mars, the Moon, and beyond.

In the coming decades, we can expect to see the establishment of permanent space habitats, mining operations on the Moon, and self-sustaining colonies on Mars—all made possible by space factories and 3D printing.

6. Conclusion

Space factories and 3D printing in space represent a bold step forward in the future of space exploration. By enabling the production of materials and infrastructure on-site, these technologies can reduce the costs and logistical challenges associated with space missions. They also open up new possibilities for long-term space exploration and colonization, allowing humanity to establish a presence beyond Earth. As we continue to develop these technologies, the dream of a self-sustaining human presence in space is closer to becoming a reality.